Rebar Corrosion: Causes, Prevention, and Treatment

Reinforcing bars, commonly known as rebar, play a crucial role in the structural integrity of concrete constructions. However, one of the significant challenges faced in the longevity of these structures is rebar corrosion. This article delves into the causes of rebar corrosion, explores effective prevention strategies, and discusses treatment options to mitigate its effects.

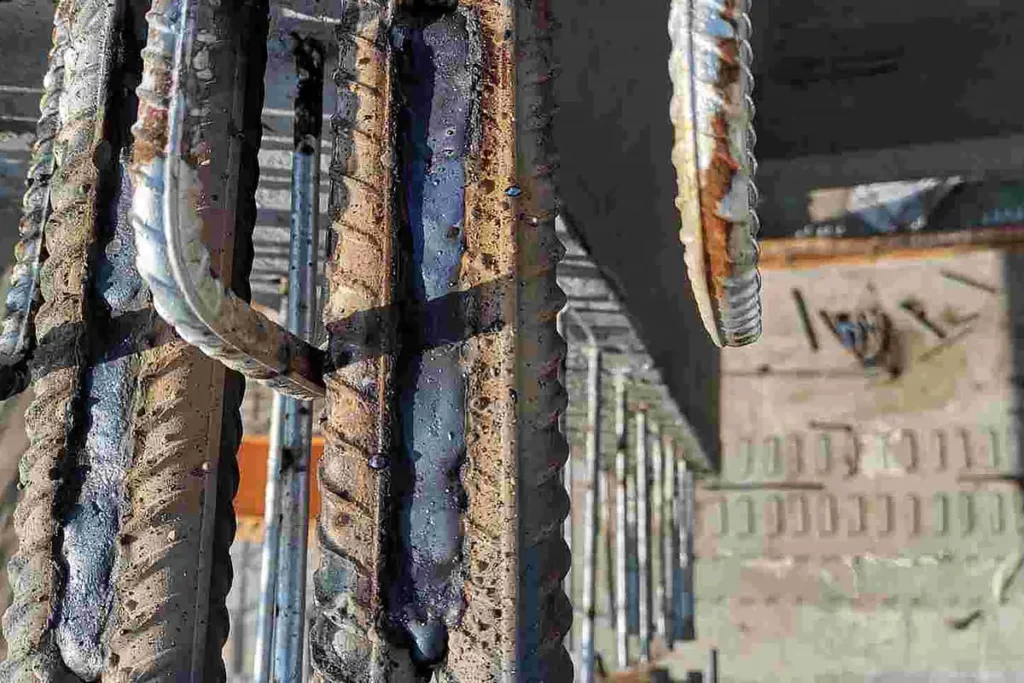

Understanding Rebar Corrosion

Rebar corrosion occurs when the steel bars embedded in concrete begin to deteriorate due to various environmental factors. This process can lead to severe structural damage, compromising the safety and stability of buildings, bridges, and other concrete structures.

The Chemistry of Corrosion

Corrosion is primarily an electrochemical process that occurs when steel is exposed to moisture and oxygen. The presence of chlorides, often from de-icing salts or seawater, can significantly accelerate this process. When these elements come into contact with the steel, they initiate a reaction that leads to the formation of rust, which expands and creates internal pressure within the concrete.

This expansion can cause cracking and spalling of the concrete cover, exposing more of the rebar to the corrosive environment. As the corrosion progresses, the structural integrity of the concrete can be compromised, leading to potential failures.

Factors Contributing to Corrosion

Several factors can contribute to the corrosion of rebar, including:

- Environmental Conditions: High humidity, exposure to saltwater, and temperature fluctuations can all increase the risk of corrosion.

- Quality of Concrete: Poor-quality concrete with inadequate cover over the rebar can lead to increased exposure to moisture and corrosive agents.

- Carbonation: The natural process of carbonation in concrete can lower the pH level, making the environment more conducive to corrosion. Read about carbonation at: https://www.health.harvard.edu/staying-healthy/does-carbonated-water-harm-bones

Additionally, the design and construction practices play a crucial role in mitigating corrosion risks. For instance, the use of corrosion-resistant materials, such as epoxy-coated rebar or stainless steel, can significantly enhance the longevity of concrete structures. Furthermore, proper drainage systems are essential to prevent water accumulation around concrete elements, which can exacerbate corrosion. Regular maintenance and inspection routines are also vital, as they allow for early detection of corrosion-related issues, enabling timely repairs and interventions.

Moreover, the impact of climate change cannot be overlooked, as it may lead to more extreme weather patterns, including increased rainfall and rising sea levels. These changes can further elevate the risk of corrosion in coastal and urban areas, where infrastructure is often subjected to harsher conditions. Engineers and architects must therefore consider these evolving environmental factors in their designs, ensuring that structures are not only built to last but are also resilient against the challenges posed by a changing climate.

Preventing Rebar Corrosion

Prevention is always better than cure, especially when it comes to rebar corrosion. Implementing effective strategies during the design and construction phases can significantly reduce the risk of corrosion occurring.

Choosing the Right Materials

Utilising high-quality materials is essential in preventing corrosion. This includes selecting concrete with low permeability and ensuring that the concrete mix is designed to withstand environmental challenges. Additionally, using corrosion-resistant rebar, such as epoxy-coated or stainless steel rebar, can provide an extra layer of protection against corrosive elements. The choice of materials should also take into account the specific environmental conditions of the project site, such as exposure to saltwater in coastal areas or de-icing salts in colder climates, which can accelerate the corrosion process. Furthermore, advancements in material science have led to the development of innovative coatings and treatments that can enhance the longevity of rebar, making it imperative for engineers to stay informed about the latest options available.

Proper Concrete Cover

Ensuring adequate concrete cover over the rebar is critical. The cover acts as a barrier between the steel and the external environment, protecting it from moisture and corrosive agents. The thickness of the cover should be determined based on environmental exposure conditions, with thicker covers recommended in harsher environments. It is also important to consider the placement of the rebar within the concrete; improper positioning can lead to areas of insufficient cover, which may become vulnerable over time. Additionally, the use of fibres in the concrete mix can help improve the overall durability and resistance to cracking, further safeguarding the rebar from potential corrosion.

Regular Maintenance and Inspections

Routine inspections and maintenance are vital for identifying early signs of corrosion. Regularly checking for cracks, spalling, or other signs of deterioration can help address issues before they escalate. Implementing a maintenance plan that includes cleaning, sealing, and repairing any damage can extend the lifespan of concrete structures significantly. Moreover, employing advanced technologies such as non-destructive testing methods can provide deeper insights into the condition of the rebar without compromising the integrity of the structure. These methods can detect corrosion beneath the surface, allowing for timely interventions that can save both time and resources in the long run. It is also beneficial to document inspection findings meticulously, as this data can inform future maintenance strategies and contribute to a more proactive approach to structural integrity management. Click here to find more about integrity.

Treatment of Corroded Rebar

Despite the best prevention efforts, some structures may still experience rebar corrosion. When this occurs, timely and effective treatment is essential to restore the structural integrity of the concrete.

Assessment and Diagnosis

The first step in treating corroded rebar is conducting a thorough assessment to determine the extent of the corrosion. This may involve non-destructive testing methods, such as ultrasonic testing or ground-penetrating radar, to evaluate the condition of the rebar without causing further damage to the structure.

Repair Techniques

Once the assessment is complete, various repair techniques can be employed, including:

- Concrete Repair: This involves removing damaged concrete and replacing it with new material. It may also include the application of surface treatments to enhance the durability of the new concrete.

- Rebar Replacement: In cases of severe corrosion, it may be necessary to replace the affected rebar. This process involves carefully removing the corroded sections and installing new rebar, ensuring proper alignment and bonding with the surrounding concrete.

- Corrosion Inhibitors: Applying corrosion inhibitors can help slow down the corrosion process. These chemical compounds can be mixed into the concrete or applied to the surface to provide additional protection.

Long-term Solutions

For long-term solutions, it is crucial to consider the implementation of protective coatings or cathodic protection systems. Protective coatings can provide a barrier against moisture and corrosive agents, while cathodic protection involves applying a small electrical current to the rebar to counteract the corrosion process.

Case Studies and Real-World Applications

Understanding the practical application of prevention and treatment strategies can be illustrated through various case studies. These examples highlight successful interventions that have extended the life of concrete structures.

Bridges and Infrastructure

Many bridges, particularly those in coastal areas, have faced significant challenges due to rebar corrosion. One notable example involved a major bridge that underwent a comprehensive rehabilitation programme. The project included the use of corrosion-resistant rebar and the application of protective coatings to the existing concrete. The result was a significant extension of the bridge’s lifespan, ensuring safety for its users.

Commercial Buildings

In commercial buildings, particularly those exposed to de-icing salts, regular maintenance and timely repairs have proven effective in combating rebar corrosion. One such building implemented a proactive maintenance plan that included annual inspections and the application of corrosion inhibitors. This approach not only preserved the structural integrity but also reduced long-term repair costs.

The Future of Rebar Corrosion Management

As technology advances, new materials and methods for preventing and treating rebar corrosion continue to emerge. Innovations such as smart concrete, which can self-heal or detect corrosion, are being researched and developed. These advancements hold the potential to revolutionise how rebar corrosion is managed in the future.

Research and Development

Ongoing research into corrosion-resistant materials and coatings is crucial for developing more effective solutions. By investing in R&D, the construction industry can better understand the mechanisms of corrosion and develop materials that can withstand harsh environments.

Education and Training

Educating engineers, architects, and construction professionals about the importance of corrosion prevention and treatment is essential. Training programmes that focus on best practices can help ensure that future projects are designed and constructed with longevity in mind.

Conclusion

Rebar corrosion poses a significant threat to the safety and longevity of concrete structures. Understanding the causes, implementing effective prevention strategies, and employing timely treatment methods are essential for mitigating its effects. By prioritising quality materials, regular maintenance, and innovative solutions, the construction industry can protect its investments and ensure the safety of its structures for years to come.

As the industry evolves, continued research and education will play a pivotal role in addressing the challenges posed by rebar corrosion, ultimately leading to safer and more durable infrastructure.

Read more at: Benefits of using reobar in concrete construction